Neuigkeiten

3D heute. Und morgen.

Aktuell sind keine Termine vorhanden.

Technologien

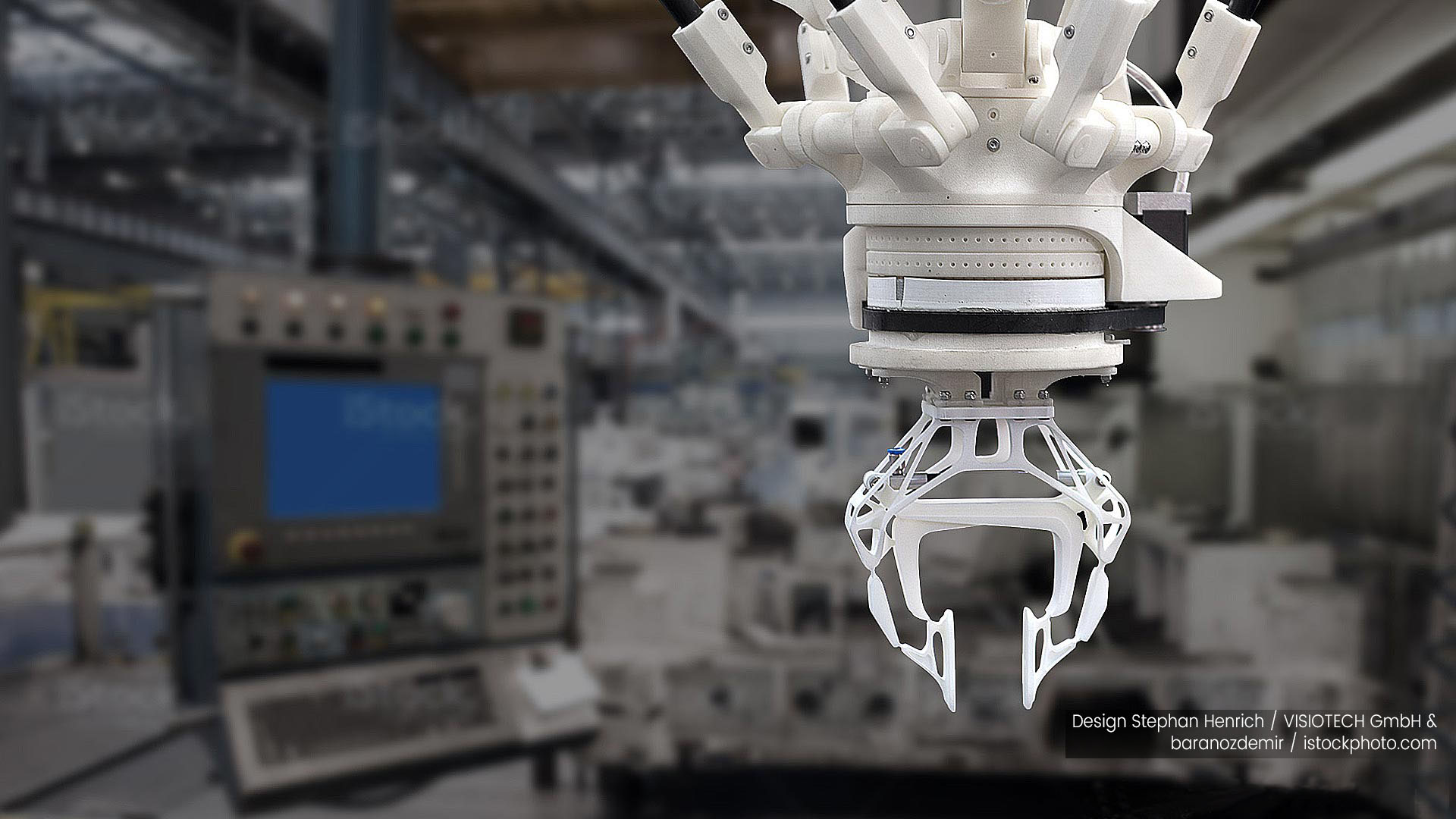

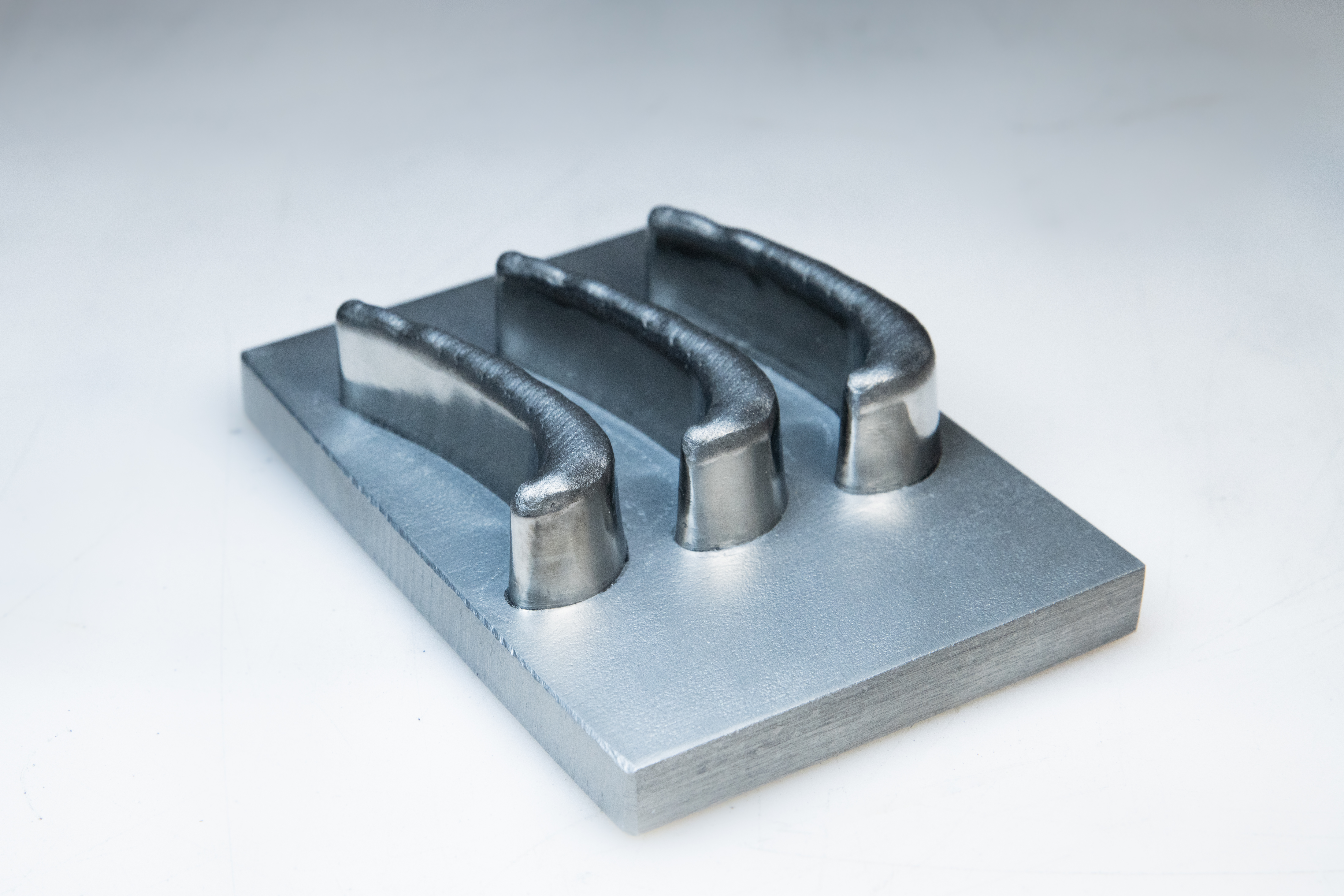

Paradigmenwechsel

Additiv-generative Fertigungsverfahren bringen werkzeuglos den richtigen Werkstoff an die richtige Stelle, mit hoher Präzision, Flexibilität, Ressourceneffizienz und Wirtschaftlichkeit. Wir gestalten die Evolution und läuten ein neues Druckzeitalter ein. Seien Sie dabei und lassen Sie uns Deutschland zum Leitanbieter für die additiv-generative Fertigung entwickeln. mehr