Technology Project

Innoadd

Objective:

Development of a laser wire deposition welding technology for the production of topologically optimized lightweight structures

Partners:

Duration: 01.01.2020 - 31.12.2021

The aim of the project is to develop a production technology for the manufacture of metallic wall structures with topology-optimized stiffeners. Within the framework of the overall project, a multi-head laser-wire deposition welding technology is to be developed and its suitability demonstrated using the example of a large demonstrator. The demonstrator is a side wall of a railway car in real component size (5 x 2 m), in which conventionally welded stiffening structures are to be replaced by topology-optimized lightweight structures produced by additives. The structures are intended to make the side walls significantly lighter, thereby reducing the operating costs of the wagon and at the same time enabling new design concepts for wagons. Thematically, the Innoadd project takes up the idea of the TopoGross project and assigns the project results and especially the identified technology limitations to new objectives and new approaches to solutions.

Procedure: Laser Wire Deposition Welding

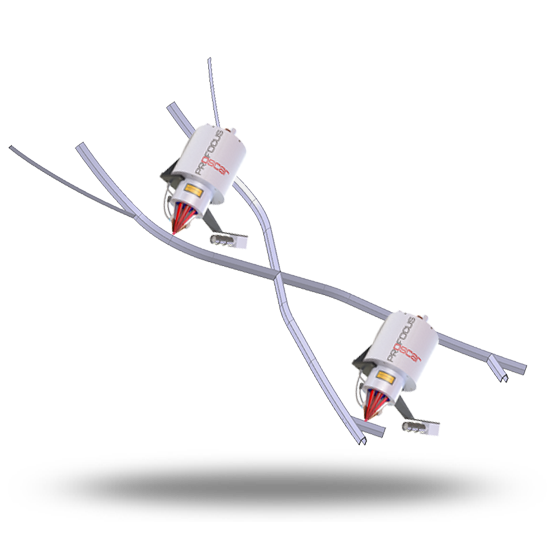

Process video to illustrate laser wire deposition welding with laser system ProFocus

Advantages

• high availability and alloy selection of wires suitable for welding

• certified wire quality

• inexpensive

• 100 % material utilization

• lower occupational safety measures in comparison with powder

• easier storage and disposal than powder material